A Comprehensive Guide to Choosing the Right Bulk Containers for Ideal Storage and Transportation

Choosing the ideal mass containers is a critical decision for organizations associated with storage and transportation. Various aspects influence this option, consisting of material compatibility and size requirements. Various markets have unique needs that must be satisfied to ensure safety and effectiveness. Understanding these components can significantly influence logistics and item honesty. The following areas will explore necessary factors to consider and ideal practices thoroughly, revealing what genuinely matters in container option.

Understanding Various Kinds of Mass Containers

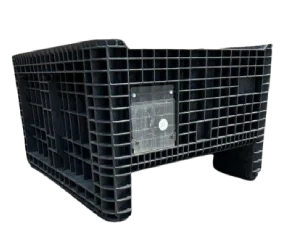

Bulk containers work as important tools in the storage space and transport of different materials, ranging from fluids to solids. These containers come in diverse forms, each made for particular applications. Usual types include Intermediate Bulk Containers (IBCs), which are ideal for transferring liquids, powders, or granules. Totes, one more variation, are ideal for both fluids and solids and can be piled for reliable storage. Additionally, mass bags, commonly made from woven material, are utilized to take care of dry bulk materials. For solid materials, mass bins provide tough, stackable alternatives that make best use of area. Each kind of bulk container offers an unique feature, facilitating effective activity and storage, while making sure safety and security and compliance with market criteria. Recognizing these options is vital for reliable logistics monitoring.

Benefits and Negative Aspects of Common Mass Container Options

When reviewing mass container options, it is important to contemplate both their benefits and disadvantages. Stiff containers, such as steel or plastic containers, provide toughness and defense against environmental variables, yet they can be larger and much less adaptable relating to storage space. On the various other hand, versatile containers, like mass bags, are lightweight and simple to manage; nonetheless, they might not supply the very same degree of security for sensitive materials. Additionally, some containers are designed for particular items, which can improve efficiency but restriction versatility. Eventually, the choice of mass container depends on balancing these advantages and drawbacks to satisfy the particular storage space and transport needs of the products included.

Key Considerations for Choosing Bulk Containers

Selecting the right mass container calls for cautious factor to consider of numerous important variables, as the choice can substantially affect both effectiveness and safety and security during storage and transportation. First, the product of the container need to straighten with the nature of the products, guaranteeing compatibility to avoid contamination or destruction. Next, the container's size and ability must match the volume of items being saved or transported, optimizing space usage. Additionally, the weight of the container is vital for both handling and transportation costs. Longevity and resistance to ecological variables are necessary for maintaining product integrity. More about the author Compliance with sector laws and criteria should be confirmed to stay clear of legal consequences. By evaluating these variables, companies can make enlightened decisions that boost operational efficiency

Industry-Specific Bulk Container Requirements

Different industries impose details needs for mass containers based upon the nature of the products managed and the regulatory landscape they run within. For instance, the food and drink industry mandates containers that are certified with health guidelines, ensuring they are safe and quickly cleanable to stop contamination. Alternatively, the chemical market often needs containers that can hold up against harsh substances, necessitating products like high-density polyethylene or steel. In drugs, mass containers must stick to strict standards to safeguard product stability and assurance traceability. Additionally, markets such see page as farming may concentrate on containers that help with oygenation or moisture control, while the building industry might focus on resilience and load-bearing ability. Each need mirrors the unique difficulties and conformity requirements of the respective market.

Best Practices for Maintaining Product Integrity During Storage and Carry

Preserving item stability throughout storage space and transport is crucial, as even minor mishandling can result in considerable losses or top quality degradation. To ensure perfect problems, temperature level and humidity levels ought to be very closely kept track of, especially for delicate materials. Utilizing suitable bulk containers created for details products is essential, as these containers supply required defense versus contamination and physical damages. Regular assessments of containers and storage space facilities can assist identify potential concerns before they escalate - Industrial Bulk Plastic Containers. Furthermore, appropriate labeling and documentation improve the taking care of procedure, reducing the threat of errors. Educating personnel in best techniques for managing and transferring products even more safeguards honesty, making sure that items reach their destination in the intended problem. Implementing these best techniques can significantly enhance overall efficiency and reliability

Often Asked Concerns

What Are the Expenses Related To Mass Container Rental Versus Purchase?

How Can I Personalize Mass Containers for Details Products?

To tailor bulk containers for particular products, one can customize features, dimensions, and products such as ventilation or insulation. Branding alternatives, shade coding, and identifying additionally enhance functionality and recognition for reliable storage and transportation.

Are There Eco-Friendly Bulk Container Options Available?

What Is the Typical Life-span of Various Bulk Containers?

The typical lifespan of mass containers varies extensively; plastic containers last 5-10 years, steel options can last 10-20 you can try these out years, while wood containers typically have a life expectancy of 3-7 years, depending on usage and maintenance.

How Do I Ensure Compliance With Regulations for Mass Container Use?

To assure conformity with regulations for bulk container usage, one should on a regular basis evaluate and understand applicable laws, maintain appropriate paperwork, conduct safety and security audits, and carry out training programs for staff members dealing with these containers. Plastic Bulk Containers.

Mass containers serve as necessary tools in the storage and transport of various materials, ranging from liquids to solids. Each type of bulk container serves a distinctive feature, assisting in reliable activity and storage space, while making certain security and compliance with sector requirements. Various sectors enforce particular demands for mass containers based on the nature of the products took care of and the governing landscape they operate within. Using appropriate bulk containers developed for certain products is important, as these containers offer essential protection against contamination and physical damage. To tailor bulk containers for details items, one can modify measurements, attributes, and materials such as air flow or insulation.